We Took The Engine Room Tour (Page Three)

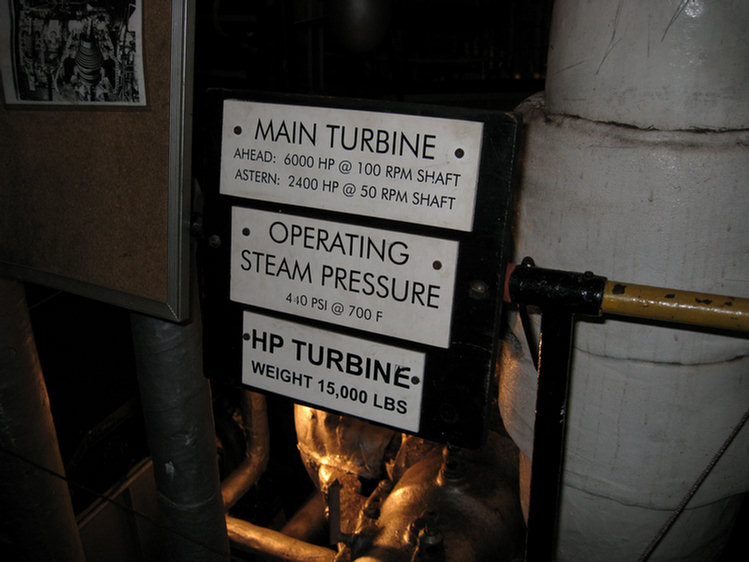

The ships needed higher speeds because of the onslaught of U-Boats. This was achieved by using improved engines like the steam turbines or diesel engines with a power output between 6000 and 8500 horsepower (4.5 and 6 MW). It also had electrically powered auxiliary equipment rather than steam powered. They were oil fired, although some Canadian vessels were completed with both bunkers and oil tanks so that they could use coal or oil.

A compound turbine is a turbine in which there are two casings, a high-pressure casing and a low-pressure casing, operating in concert to extract work from a single source of steam. The steam is partially expanded in the high-pressure casing, then exhausted to the low-pressure casing. The rotor arrangement can be either tandem-compound in which the two axles are joined end to end, or cross-compound in which the two turbines have separate axles. In the cross-compound case two separate generators are usually supplied, although a gearbox can reduce this to one.

The principal advantages of compound turbines are the reduction in size of any one casing, the confinement of the highest pressure to the smaller casing (which may be made of stronger and more expensive materials) and the possibility of divided flow in the low-pressure casing for the purpose of equalizing end thrusts.

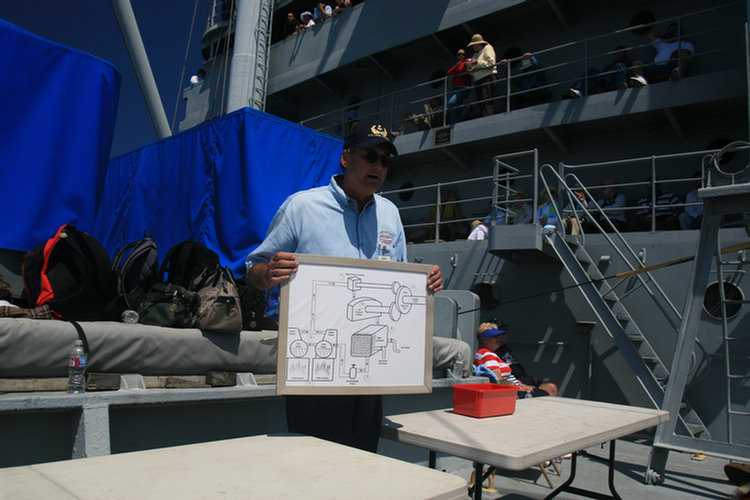

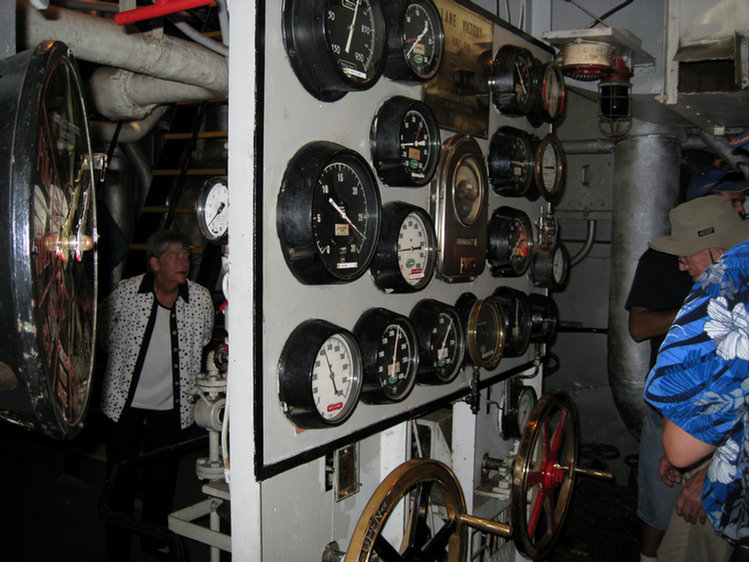

He was a great speaker and seemed to know his stuff!

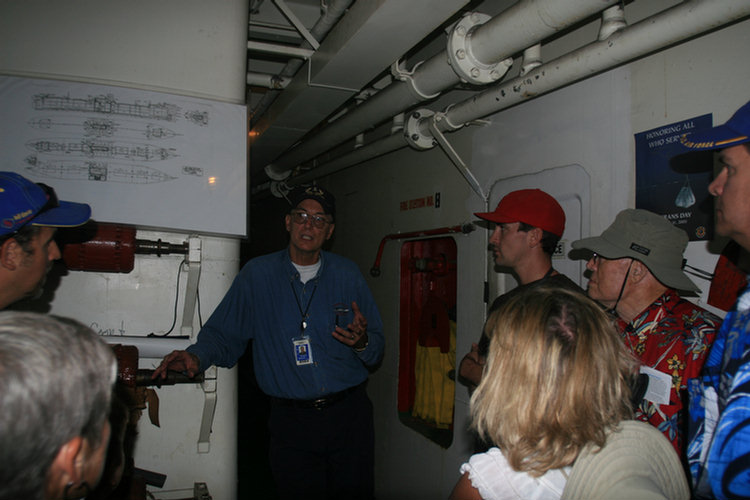

It was cool here but right through the door,

we entered the sauna known as the engine room

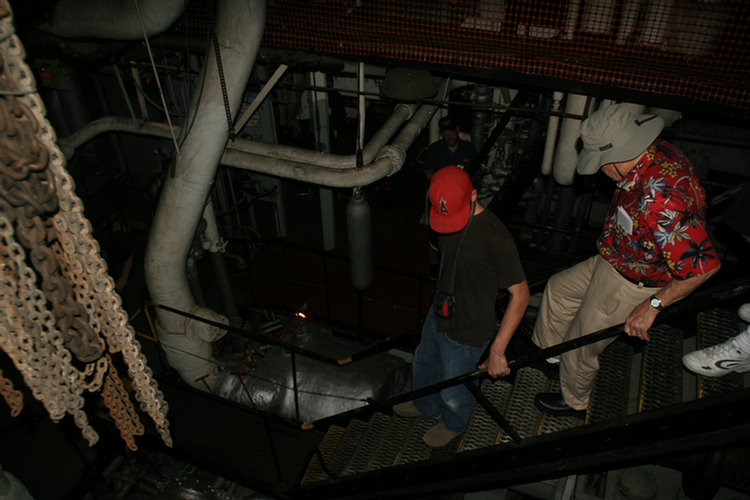

The fellow in red just turned 90 years old!

She is brave... White jacket in a greasy engine room??

What was she thinking?

We Learned A Lot On This Adventure

Did You Know? -

In physical chemistry, and in engineering, steam refers to vaporized water. It is a pure, completely invisible gas (for mist see below). At standard temperature and pressure, pure steam (unmixed with air, but in equilibrium with liquid water) occupies about 1,600 times the volume of an equal mass of liquid water. In the atmosphere, the partial pressure of water is much lower than 1 atm, therefore gaseous water can exist at temperatures much lower than 100 C (see water vapor and humidity).

In common speech, steam most often refers to the white mist that condenses above boiling water as the hot vapor ("steam" in the first sense) mixes with the cooler air. This mist is made of tiny droplets of liquid water, not gaseous water, so it is no longer technically steam. In the spout of a steaming kettle, the spot where there is no condensed water vapor, where there appears to be nothing there, is steam.

The reason so many died was when a torpedo hit,

the 700 degree steam at 400 pounds per inch was

all over the engine room destroying

everything and everyone in sight!

Look carefully at the back wall, one can see the oil flow into the boilers.

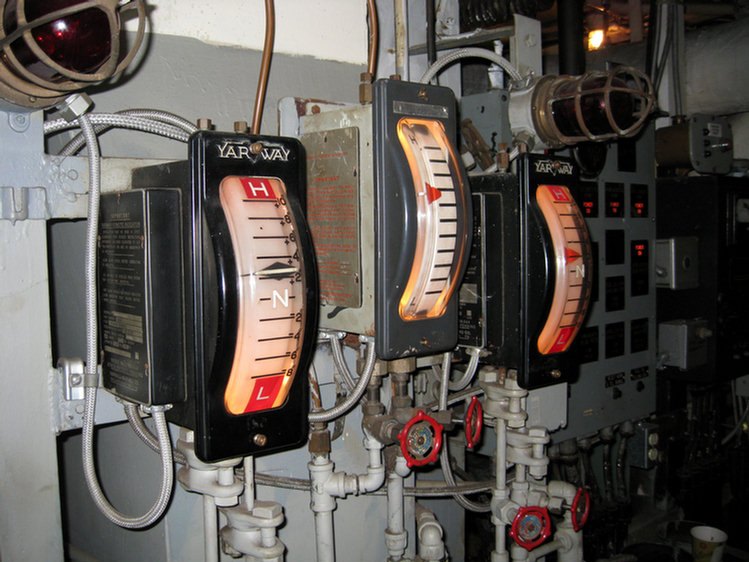

Visual indicators were everywhere making it easy to monitor what s going in with the engine!

Did You Know? -

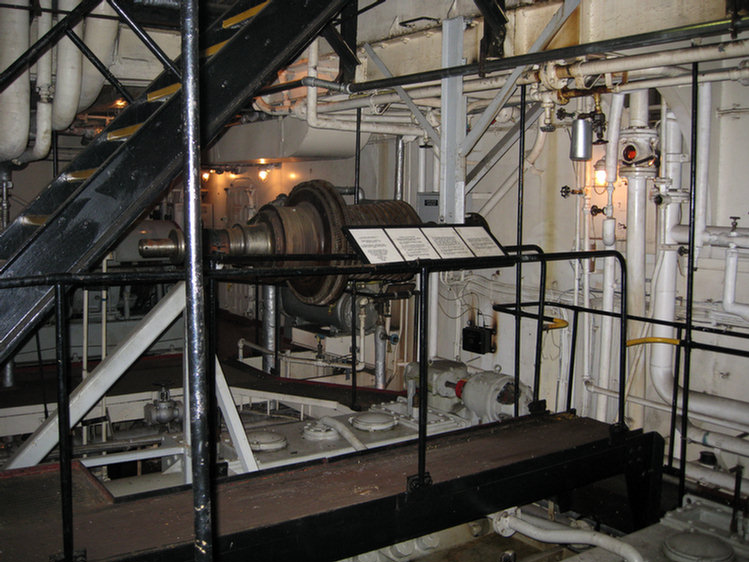

It takes 35 men to run the engine room! A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into useful mechanical work.

It has almost completely replaced the reciprocating piston steam engine (invented by Thomas Newcomen and greatly improved by James Watt) primarily because of its greater thermal efficiency and higher power-to-weight ratio. Because the turbine generates rotary motion, it is particularly suited to be used to drive an electrical generator - about 80% of all electric generation in the world is by use of steam turbines. The steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency through the use of multiple stages in the expansion of the steam (as opposed to the one stage in the Watt engine), which results in a closer approach to the ideal reversible process.

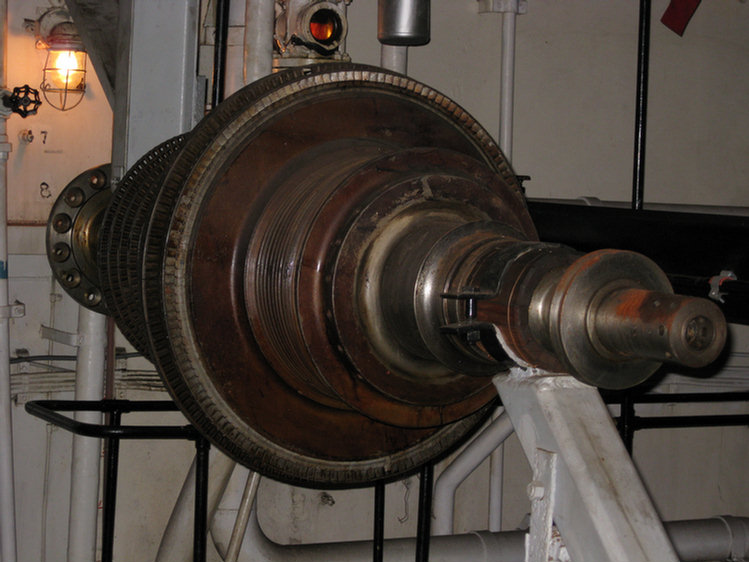

The entire ship is powered by a turbine blade like the one on display here!

It's not the normal running of the engine that takes so much time and manpower, it is the startup and shutdown. When warming up a steam turbine for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. Also a turning gear is engaged when there is no steam to the turbine to slowly rotate the turbine to ensure even heating to prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10 to 15 RPM to slowly warm the turbine.

Problems with turbines are now rare and maintenance requirements are relatively small. Any imbalance of the rotor can lead to vibration, which in extreme cases can lead to a blade letting go and punching straight through the casing. It is, however, essential that the turbine be turned with dry steam. If water gets into the steam and is blasted onto the blades (moisture carryover) rapid impingement and erosion of the blades can occur, possibly leading to imbalance and catastrophic failure. Also, water entering the blades will likely result in the destruction of the thrust bearing for the turbine shaft. To prevent this, along with controls and baffles in the boilers to ensure high quality steam, condensate drains are installed in the steam piping leading to the turbine.

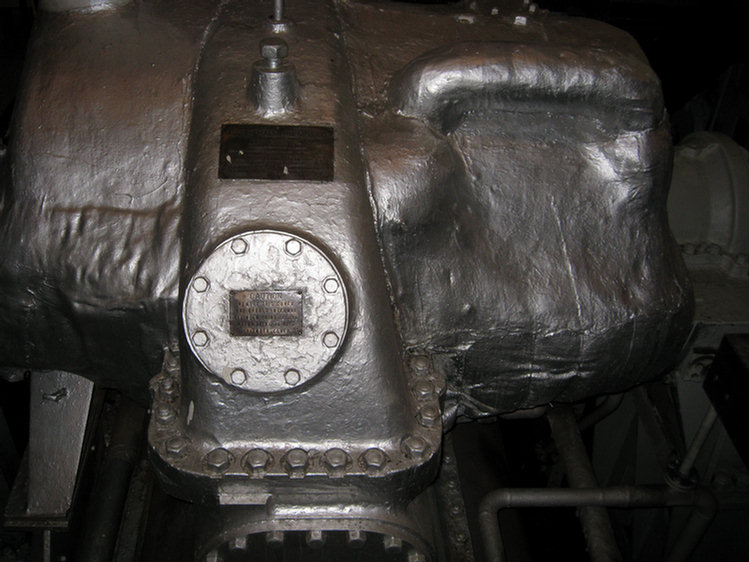

Steam Condenser Plays an Essential Role

Did You Know? - The steam turbine itself is a devise to convert the heat in steam to mechanical power.

The difference between the heat of steam per unit weight at the inlet to turbine and the heat of steam per unit weight at the outlet to turbine represents the heat given out (or heat drop) in the steam turbine which is converted to mechanical power. The heat drop per unit weight of steam is also measured by the word enthalpy drop.

Therefore the more the conversion of heat per pound (or Kg) of steam to mechanical power in the turbine, the better is its performance or otherwise known as efficiency.

By condensing the exhaust steam of turbine, the exhaust pressure is brought down below atmospheric pressure from above atmospheric pressure, increasing the steam pressure drop between inlet and exhaust of steam turbine.

This further reduction in exhaust pressure gives out more heat per unit weight of steam input to the steam turbine, for conversion to mechanical power. Most of the heat liberated due to condensing, i.e., latent heat of steam, is carried away by circulating water inside the tubes.

10,000 gallons of seawater a minute is pumped into

the condenser in order to cool the steam before it goes back for reheating!

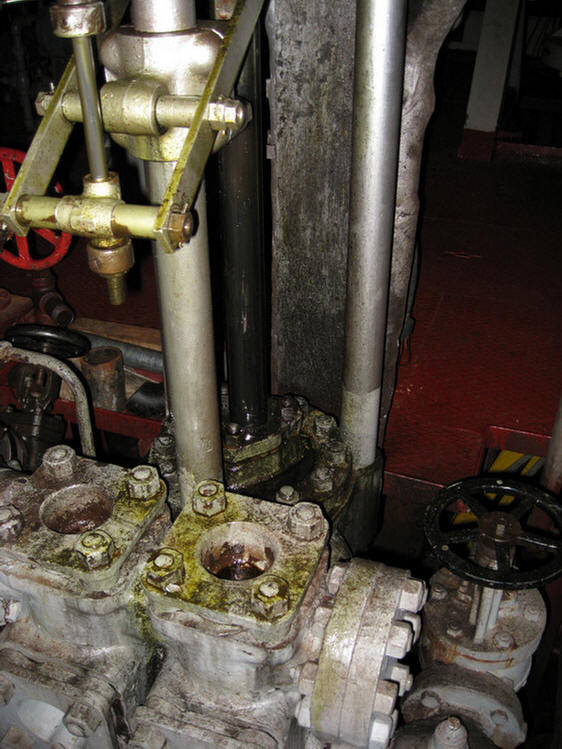

The seawater enters the ship through this valve on the bottom of the ship!

This pump makes sure that the 10,000 gallons a minute is forced into the condenser! Note the glass at the top, a simple way of making sure that water is flowing... Do not trust instruments... trust your eyes!

The output of the condenser is routed through these pipes to the outside of the ship where the slightly heated seawater is sent on its way!

The condenser as built the year I was born!

Hotter Than Hell (Well, Not Really)

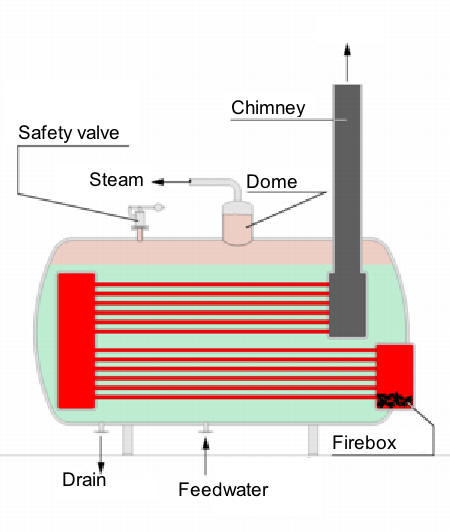

Did You Know? - A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.

Hot was not even close to what it looked like!

Did You Know? -

Most boilers heat water until it boils, and then the steam is used at saturation temperature (i.e., saturated steam). Superheated steam boilers boil the water and then further heat the steam in a superheater. This provides steam at much higher temperature, and can decrease the overall thermal efficiency of the steam plant due to the fact that the higher steam temperature requires a higher flue gas exhaust temperature. However, there are advantages to superheated steam. For example, useful heat can be extracted from the steam without causing condensation, which could damage piping and turbine blades.

Superheated steam presents unique safety concerns because, if there is a leak in the steam piping, steam at such high pressure/temperature can cause serious, instantaneous harm to anyone entering its flow. Since the escaping steam will initially be completely superheated vapor, it is not easy to see the leak, although the intense heat and sound from such a leak clearly indicates its presence.

The superheater works like coils on an air conditioning unit, however to a different end. The steam piping (with steam flowing through it) is directed through the flue gas path in the boiler furnace. This area typically is between 1300-1600 degrees Celsius (2500-3000 degrees Fahrenheit).

Some superheaters are radiant type (absorb heat by radiation), others are convection type (absorb heat via a fluid i.e. gas) and some are a combination of the two. So whether by convection or radiation the extreme heat in the boiler furnace/flue gas path will also heat the superheater steam piping and the steam within as well.

It is important to note that while the temperature of the steam in the superheater is raised, the pressure of the steam is not: the turbine or moving pistons offer a "continuously expanding space" and the pressure remains the same as that of the boiler.

"Are you fooling me? I am an engineer!"

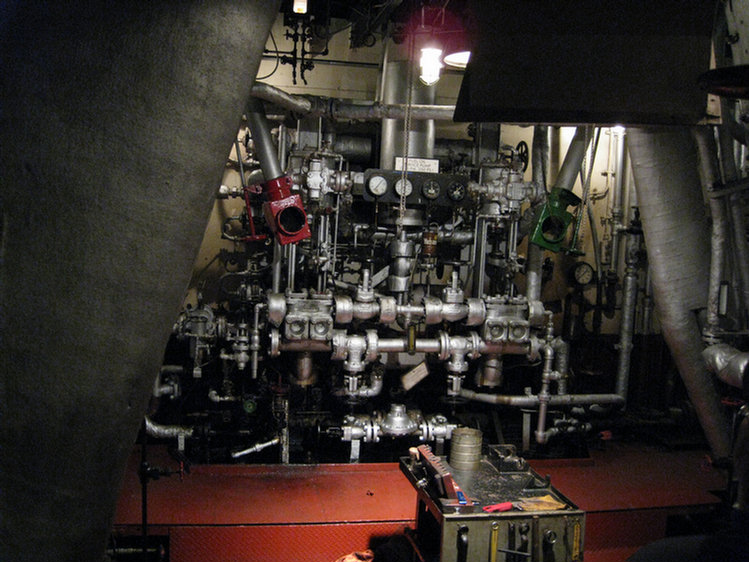

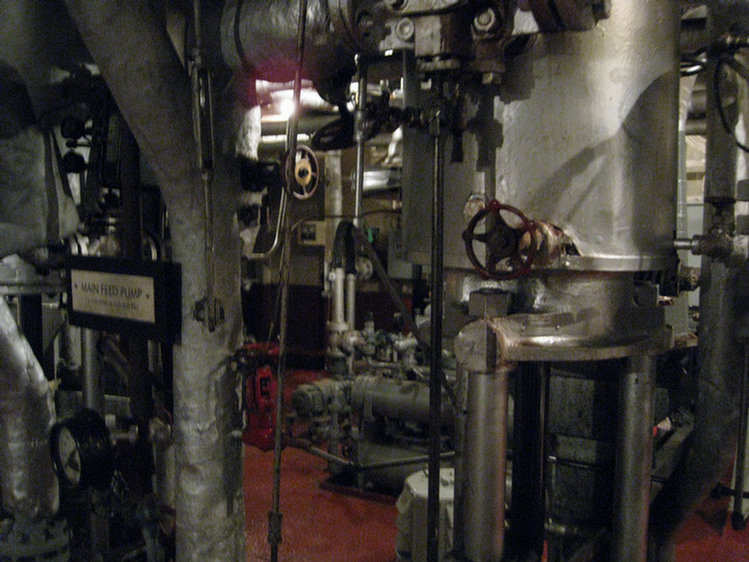

Much of the piping and valves are for backups and

startup/shutdown and maintenance!

A good year!

Plumbers Delight!

Shaft Alley

It was cool down the 170' shaft only because the engine room was hot, drawing the heat up and forcing outside air to come into shaft alley! Great breeze. This was also the escape tunnel for the engineer room folks should they need to get out quick!

Did You Know? -

A propeller is the most common propulsion on ships, imparting momentum to a fluid which causes a force to act on the ship .

The ideal efficiency of any size propeller is that of an actuator disc in an ideal fluid. An actual marine propeller is made up of sections of helicoidal surfaces which act together 'screwing' through the water (hence the common reference to marine propellers as "screws"). Three, four, or five blades are most common in marine propellers, although designs which are intended to operate at reduced noise will have more blades. The blades are attached to a boss, which should be as small as the needs of strength allow - with fixed pitch propellers the blades and boss are usually a single casting.

A driveshaft, driving shaft, propeller shaft, or Cardan shaft is a mechanical device for transferring power from the engine or motor to the point where useful work is applied. Most engines or motors deliver power as torque through rotary motion: this is extracted from the linear motion of pistons in a reciprocating engine; water driving a water wheel; or forced gas or water in a turbine. From the point of delivery, the components of power transmission form the drive train.

Driveshafts are carriers of torque: they are subject to torsion and shear stress, which represents the difference between the input force and the load. They thus need to be strong enough to bear the stress, without imposing too great an additional inertia by virtue of the weight of the shaft.

On a power-driven ship, the driveshaft, or propeller shaft, usually connects the transmission inside the vessel directly to the propeller, passing through a stuffing box or other seal at the point it exits the hull.

The Transmission Was Connected To Both Turbines (High and Low Pressure)

This little guy generate 6,000 horsepower when hit

with a stream of super-heated steam! Wow!

The Control Station And Exit

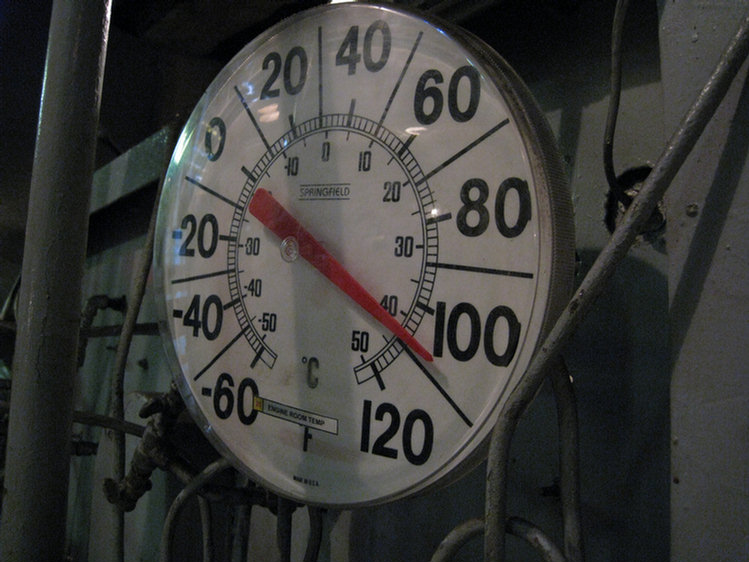

By the end of the day, the engine room is generally 115-120 degrees.

Do not touch anything!

Look at the pulley behind the lever...

This is what the captain uses to change speed of the engine!

The speed control station! Everything is measure in terms

of heat and pressure form this spot!

The more important the measurement, the bigger the measuring device!

Very Nice Young Man

This young man and his dad were on vacation from Utah. The little boy was able to identify by name and model number every WWII airplane on my shirt! HE loves history! Very impressive

Low pressure turbine

Time for some air and cool off! Go outside and listen for the potential attack by the forces of evil!